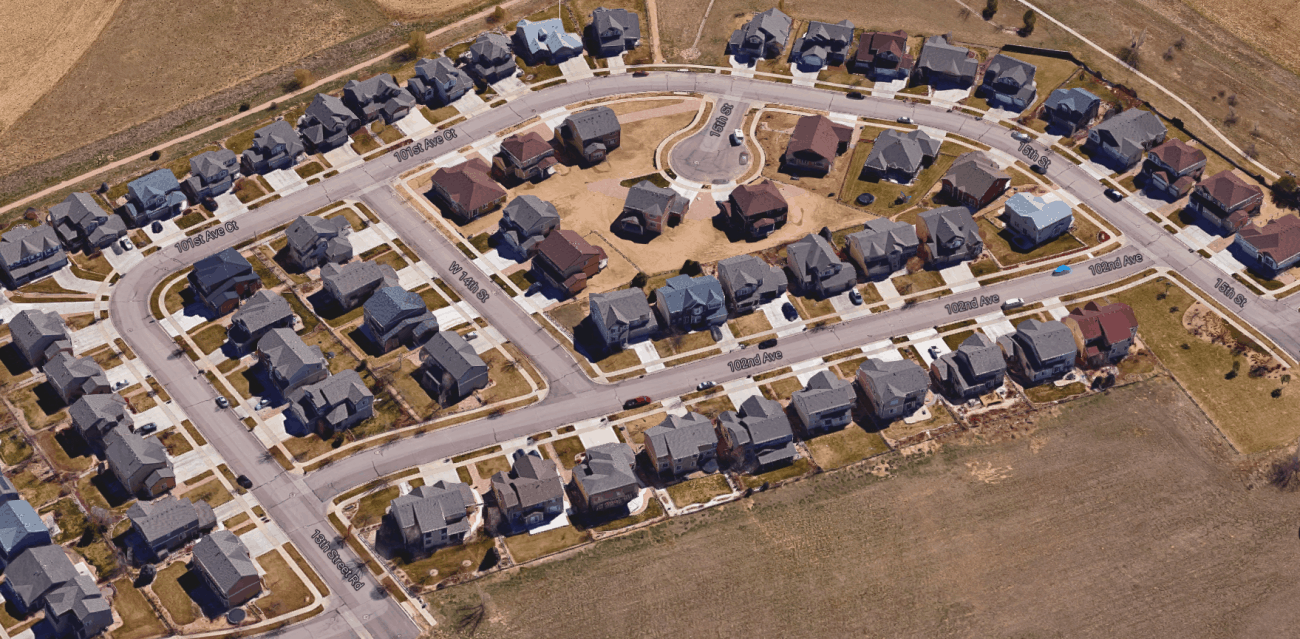

2016 Demonstration Seal Coat Program

In the Promontory Subdivision - Greeley, CO

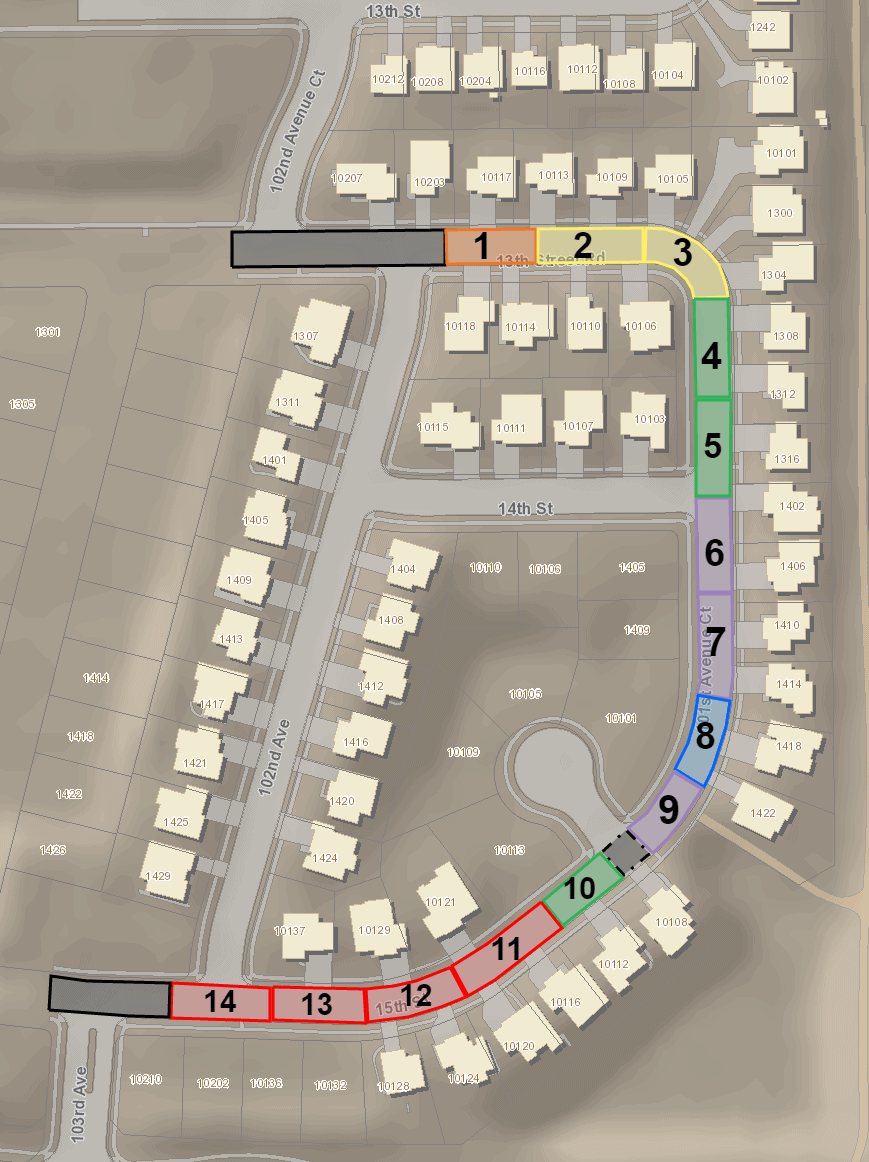

Greeley remains at the forefront of the busy Asphalt maintenance industry. Preserving the infrastructure of a city with 100,000+ population is not an easy task. It’s critical that we take advantage of and test new developments in the construction field. In an effort to evaluate the current seal coating products on the market today, Greeley selected a section of road to test a variety of materials side-by-side. A seal coat is an asphalt maintenance technique where a layer of oil emulsion and sometimes fine aggregate is lain on the surface of a roadway. This process slows oxidization, helps to lock in surface oil, and inhibits crack formation. Between July and October of 2016, 14 different seal coat materials were tested in the Promontory neighborhood’s Southern half. See below for more information on each section.

The bar graph to the right features a series of scores for each section. This score is a combination of nine criteria upon which the fourteen section’s overall quality and durability can be compared. Beginning in February 2017, the Public Works Department will be adding section-specific data, reflecting our findings on a monthly basis.

Composite Scores by Section

- 1 – HA5 68%

- 2 – Reclamite (0.05 gal/sy) 39%

- 3 – Reclamite (0.07 gal/sy) 39%

- 4 – .25″ Chip Seal 73%

- 5 – Type II Slurry 60%

- 6 – USS Type III 44%

- 7 – GSB-88 63%

- 8 – RS-90 67%

- 9 – USS Type II 66%

- 10 – Fabric & Double 0.375″ Chip Seal 60%

- 11 – MasterSeal 57%

- 12 – Polymer Modified MasterSeal 60%

- 13 – Liquid Road 55%

- 14 – Colorpave HD 500 40%

Click the buttons on either side of the map to learn more about each section.

Survey

We would like to know what each of you thinks of individual seal coating material in each section, what looks great or drives well, what’s working and what’s not.